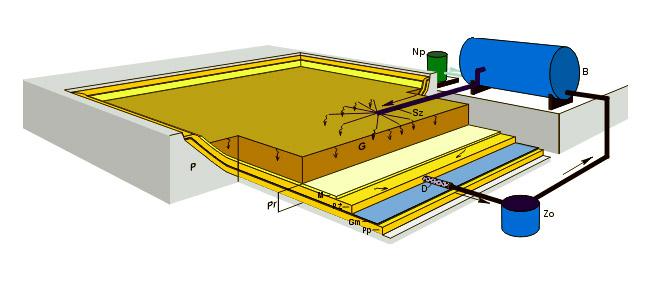

Water from pumping wells flows to the water purifying system where preliminary water purification proceeds and then goes to inoculum preparation unit and bioreactor. In the inoculum preparation unit bacterial concentrate is produced what is a parent substance to biologicals produced in the bioreactor. The bioreactor produces biologicals in the quantity needed to proceed application. Biologicals are delivered from the bioreactor to contaminated zone by application system. Then bacteria strains cooperation cause decomposition of hydrocarbons in ground.

In order to keep the ground purification process effective mineral ingredients and nutrients must be added in stages of producing bacterial concentrate in the inoculum preparation unit and biologicals in the bioreactor. Other important factors are: oxygen access to ground, surroundings temperature and moisture. Therefore sometimes additional ground venting via e.g. applying wells or watering via e.g. sprinkling is applied.

Ground purification process is continuously monitored by chemical and microbiological analyses of ground and water samples. The analyses results form the basis for decision making referring to reclamation process continuing and its final completion.

Ground purification by “IN-SITU” biotechnological methods is a long-term process. It depends on local conditions but often requires from 2 to 10 years to complete.

Remediation – Free floating product removal

Many of commonly used oil derived substances such as fuels (petrols, diesel oil) are non-polar compounds and lower in density then water, therefore reaching water level they form a floating layer of free product. Before the biotechnological reclamation starts the layer of oil derived substances floating on water table should be removed in order to enable applying and improve the efficiency of biotechnological methods.

Free floating product is removed by pumping system consisted of wells equipped with skimmers that allow to pump separately water and oil product. The system, that DEKONTA Polska Sp. z o.o. offers, guarantee air-tight process and pneumatic product transport what makes it safe and suitable for explosion danger zones, e.g. within fuel stores or refineries.