Have your neighbours complained about unpleasant odours emitted from your factory?

Does your company discharge waste gases containing volatile organic compounds (VOCs) or inorganic compounds like ammonia (NH3) and hydrogen sulfide (H2S)?

Does your plant comply with your national and European emission regulations?

Our bio-treatment systems are the right solution:

- Biofilters with scrubbers

- Biotrickling filters

PROVEN SOLUTIONS TO AIR EMISSION ISSUES

- Efficient (full degradation of complex mixtures of pollutants)

- Safe (no combustion source needed)

- Environmental friendly (pollutants are transformed into harmless products and a small amount of water, chemicals and energy are needed

- Cost-effective (lower investment & operating costs than conventional technologies*)

* like thermal, catalytic incineration or activated carbon systems

APPLICATIONS

Our bio-treatment systems are widely used in the following industries or sectors:

- Chemicals & polymers

- Waste Water Treatment & Composting

- Textiles & Fiberglass

- Paints & Coatings

- Food & Beverage

- Flavourings & Tobacco

- Rendering & animal breeding

- Paper & Printing

- Pharmaceuticals & Cosmetics

WHY OUR CLIENTS CHOOSE US?

Dekonta is an international supplier of bio-treatment systems throughout Europe and Asia, suppling dozens of systems. Among our clients are medium-size to multinational companies in a variety of industrial sectors.

Since 1992, we have adopted a policy of continuous development. Our R&D department has filed more than 50 patents, leading to many innovations in the field of the waste air treatment. We are able to treat complex waste gas mixtures even in the presence of particulate matter. In addition, thanks to our mesophilic, thermotolerant and thermophilic bacteria, we can process waste gas streams with temperatures up to 75° C. This means:

- No need of a cooling system

with an important saving on investment and operating costs (energy consumptions).

Thanks to this innovative concept, Dekonta offers a more competitive and unique portfolio for your waste gas treatment. Our technology won a seal of excellence from the European Commission.

We provide a customized and turnkey service that includes:

- Waste gas analyses & pilot-scale testing at your site

- Designing & delivering

- Installations & maintenance

- Air monitoring

Contact us in order to get more detailed information and a quotation.

BIOFILTERS WITH SCRUBBER

This is used for large flow rates, odour issues and low pollutant concentrations.

HOW DOES IT WORK?

The raw gas is passed through a scrubber to regulate the moisture balance and removes any presence of non-biodegradable or semi-biodegradable compounds (such as ammonia, hydrogen sulfide, etc.). Afterwards, the stream is passed through a bed of biologically active material: the pollutants are adsorbed and processed by specific micro-organisms into carbon dioxide, water, inorganic salts and biomass.

We can provide closed and enclosed biofilter beds according to the clients’ requirements and site conditions.

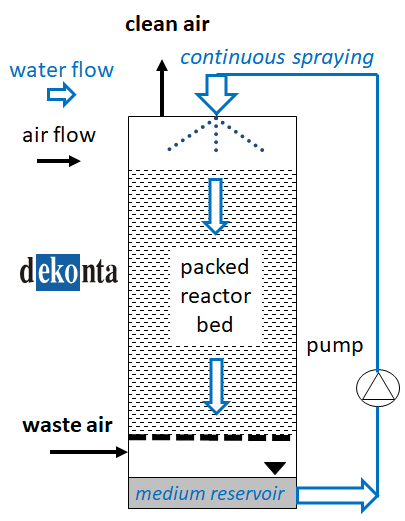

BIOTRICKLING FILTERS

In case of:

- A smaller area available for the installation

- Need of a longer biofilter bed’s life

- A better process control (pH, conductivity, nutrients, salt concentrations)

a biotrickling filters is the best solutions.

HOW DOES IT WORK?

This system is a biological scrubber where the waste gas is dissolved into a liquid phase. The pollutants are then biologically biodegraded.

The packed bed column includes a mixed culture of pollutant-degrading micro-organisms naturally immobilized and bonded to it. The packing material is constantly moisturized and it provides sufficient surface for the microorganism’s growth.